3D coordinate measuring technology, optical metrology and industrial computed tomography

Do you require initial sampling of your component or calibration certificates for your special gauges? With our many years of know-how and extensive range of machinery, we are your full-service provider for the calibration of your special gauges as well as 3D measurement and initial sampling of your components.

In the world of industrial manufacturing, every micrometre counts. At Testo Industrial Services, we use state-of-the-art coordinate measuring technology, accredited calibration and comprehensive 3D surveying to ensure that your gauges, master parts and workpieces meet the highest requirements. Thanks to a wide range of measuring methods, it is possible to record a wide variety of geometries and parameters – adapted to the shape, materials and applications. Our experienced team supports you with tactile and optical measurement methods, in-depth expertise and individual advice.

The expansion of the dimensional laboratory to include coordinate measuring technology and optical 3D measurement technology provides a comprehensive service portfolio.

Your advantage: Our competence

- Measurement of individual components on four high-precision coordinate measuring machines (CMM)

- CMM measurement uncertainty of 1.5 µm + L/450

- Test reports (EMPB) for your workpieces and components

- DAkkS-accredited calibration in coordinate measuring technology of prismatic, conical and spherical workpieces up to 3 metres

- Optical and tactile 3D measurements of geometries using coordinate measuring technology, fringe light projection and industrial computed tomography

Insight into our laboratory

Opens video in overlayThe setting of Youtube cookies is blocked until an active click on the play button is made. With this click, you give your consent for Youtube to set cookies on the terminal device you are using. You can find more information on our data protection page.

Opens video in overlayThe setting of Youtube cookies is blocked until an active click on the play button is made. With this click, you give your consent for Youtube to set cookies on the terminal device you are using. You can find more information on our data protection page.ISO and DAkkS accredited calibrations for your gauges and master parts

Gauges and master parts must be calibrated regularly to ensure proper use. This guarantees reliable and standard compliant measurement results in all manufacturing companies. With our high precision coordinate measuring machines and a well-established calibration process, we are ideally equipped to measure your gauges and master parts.

We specialise in:

- Specialised gauges

- Master parts based on technical drawings

- Adjustment rings and adjustment mandrels with shape deviations

- Gear gauges

- And many other traceable testing devices

3D surveying and initial sampling of your workpieces and components

In addition to our calibrations, we offer comprehensive services in the field of 3D measurement. Various methods enable the measurement of a wide variety of workpieces and their requirements – from classic regular geometries to complex free-form surfaces. Whether gear wheels, housings, injection-moulded parts or medical technology components – with the help of our wide range of measuring equipment and a swivelling measuring head, we can find a suitable solution for your measuring task, optionally in the form of an initial sample test report.

We specialise in:

- Gears (various types of gear teeth)

- Worm gears

- Housings

- Covers

- Surface tracing

- Smallest components

- And many other different components

As part of the initial sampling process, we create initial sample test reports (EMPB) for you in accordance with VDA standards and your specifications. A test report documents all relevant characteristics of your component. It provides a reliable basis for series approval and allows quality requirements to be traced transparently.

Our measurement methods for 3D surveying and initial sampling

Various methods are used depending on the test task and the workpiece: Testo Industrial Services offers tactile coordinate measurement technology, optical measurement with structured light projection and industrial computed tomography.

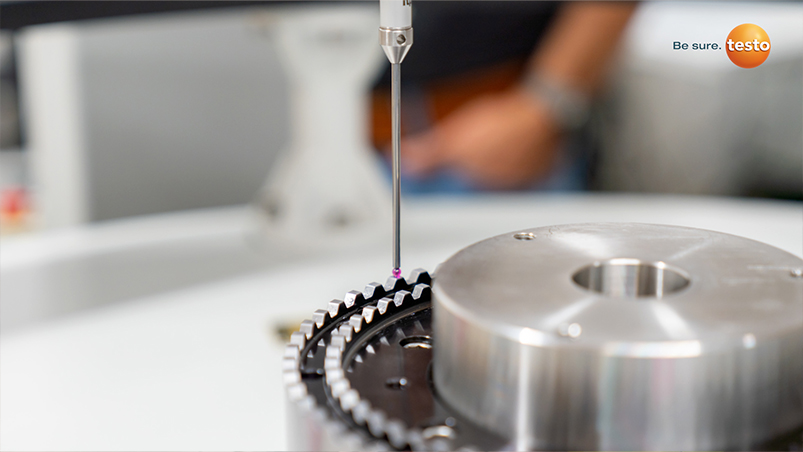

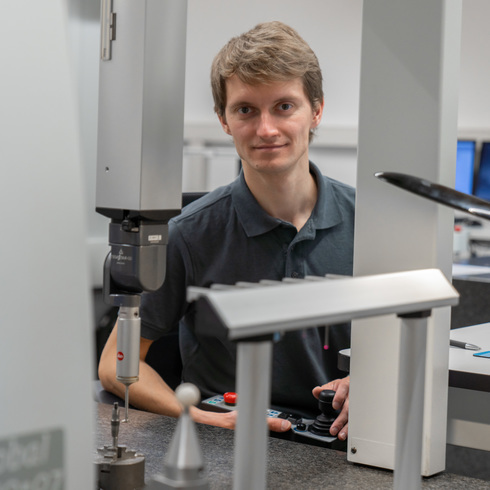

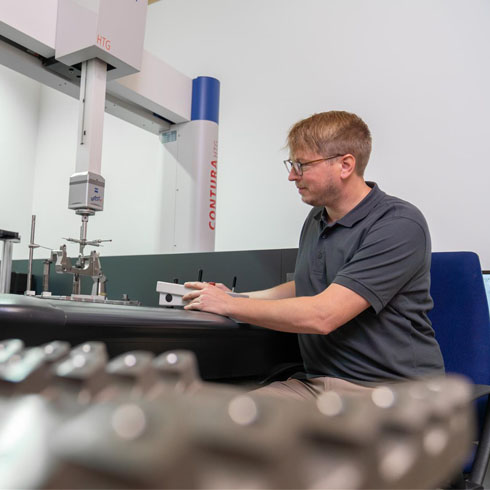

Tactile coordinate measuring technology

With our high-precision coordinate measuring machines, we capture the classic geometries of your components tactilely and reliably. Coordinate measuring technology enables the exact measurement of form and position tolerances – both for standard geometries and complex free-form surfaces.

Our measuring systems operate with a measurement uncertainty of up to 1.0 µm + L/450 and cover a measuring range of up to 3 metres. This enables us to test even large workpieces in accordance with standards.

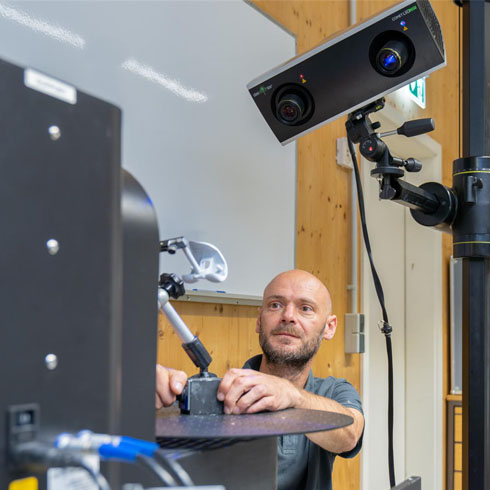

Optical measurement with structured light projection

In addition to tactile measurement methods, we are also able to perform optical measurements using 3D scanning techniques. The geometric shape of the object being measured is recorded without contact, based on the physical principles of reflection and absorption. This enables us to digitise unknown free-form surfaces and perform surface reconstruction.

The high stability of the mechanical design and the optics specially developed for the COMET L3D sensor guarantee maximum measurement accuracy. The high-precision structured light projection and the integrated rotary and swivel table ensure optimal capture of all surfaces, corners and edges of your component.

Industrial computed tomography

The smallest geometries or internal structures require the use of industrial computed tomography. Using X-rays, a computed tomography scanner captures the entire component in a non-destructive manner. The resulting digital image can be analysed and evaluated in terms of structures and dimensions.