Medical technology: validation of an injection molding process

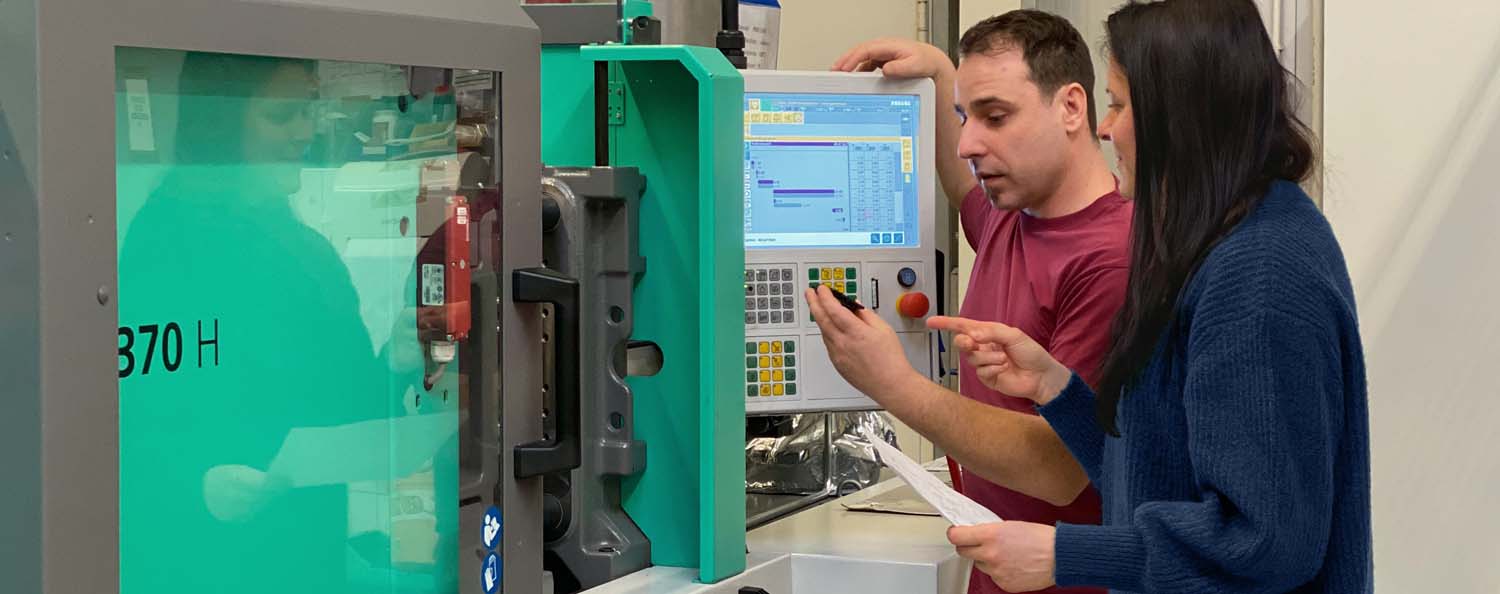

For HEMA Formenbau und Kunststoffverarbeitung GmbH, a supplier for the medical technology industry, Testo Industrial Services took over the validation of an injection molding process as well as the qualification of an injection molding system.

The company HEMA produces injection molded parts for various industries. These include companies from the automotive industry, medical technology, and the optical and electrical industries. The range of services also includes mold making of injection molds and die casting tools as well as the production of technical injection molded parts from a wide variety of plastics.

According to DIN EN ISO 13485, manufacturers of medical products are obliged to provide evidence of qualification of plants and validation of production processes at their supplier companies. Therefore, HEMA was requested by a customer in the medical device industry to qualify its injection molding equipment and validate the associated injection molding process for the production of parts that will later be incorporated into a medical device. As a highly specialized service company, Testo Industrial Services acted as an interface between Hema as a supplier and the company from the GxP-regulated industry and took over the holistic handling of the qualification and validation project.

Your advantage: Our competence

- Creation of a validation master plan to verify an established, existing process

- Carrying out a risk analysis (FMEA)

- Preparation and execution of the installation qualification, functional qualification and performance qualification.

- Preparation of a final validation report with evaluation

- Interface function of Testo Industrial Services between the requirements and specifications of the end customer and the practical implementation of the same at the supplier HEMA

Validation

Ensures the stability and robustness of processes

Qualification

GMP-compliant qualification of cleanrooms, plants & utilities, transport & warehouses

Service portfolio

Your partner for calibration, test equipment management, qualification and validation