Metrological testing services

Metrological testing services are very essential in the field of quality assurance for the measurement technology. As a metrological service provider, we solve your individual testing tasks according to your specifications within a wide range of areas.

Beyond the calibration of your measuring instruments, our metrological know-how enables us to offer testing services. These include HV tests, the preparation of initial sample test reports and the performance of machine capability tests. Here, we carry out the necessary measurements to determine metrological characteristics on measuring devices and dimensional standards and to confirm the defined compliance with specifications. The documentation takes place by the preparation of test protocols and test reports.

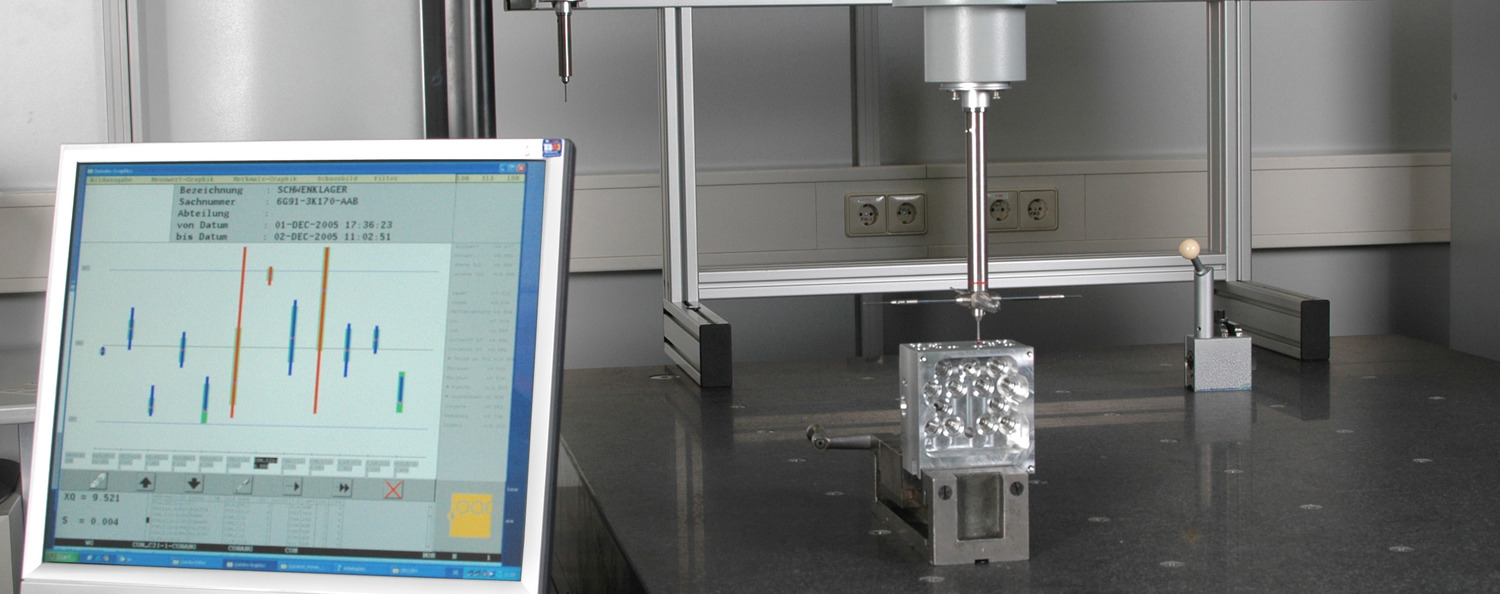

Initial sample inspection reports (ISIR)

Initial sample inspection reports are an elementary part of the sampling process, where the nominal and actual values are documented. The creation of initial sample inspection reports for your workpieces, components or even complete assemblies and clamping devices can be carried out in our dimensional laboratory. For this purpose, tactile measurement technology is used by our CMMs as well as optical measurement technology in the form of our strip light projector and 3D scan process. The measuring equipment we use enables us to measure the smallest components with a large number of measuring points, large components over a measuring range of up to 3 meters, as well as geared components and any free-form surfaces.

HV tests

The electrical safety of high-voltage components is becoming increasingly important, not only in the field of electromobility. Common test procedures and services are required for the industry and its tools and test equipment.

We can conduct electrical dielectric strength and insulation tests for you in our electrical laboratory according to DIN 61010-31 in our bowl bath. Voltage ranges up to 5 kV can be covered without any problems. Beside measuring modules, adapters, cables, test equipment, insulation tests can be carried out for any components.

Machine capability inspection (MCS)

When examining the machine capability, the stability and reproducibility of the machine is determined as a process influencing variable. Thus, statements can be made about the expected machine-related process errors and reference can be made to specified quality requirements. The determination of capability indices for the evaluation of the machine Cm and Cmk are important components of the MCS. The fields of application of machine capability studies are manifold. We carry out bolt case-related MCSs according to VDI/VDE 2645 or MCSs according to DIN ISO 22514 in the laboratory and also at your site.

Consulting Services

Measurement system analysis (MSA)

The MSA procedure 1 according to AIAG or proof of suitability according to VDA Volume 5 is the first and essential step in the assessment of your newly introduced or modified measuring equipment or measuring systems. The aim of procedure 1 is to determine the accuracy and repeatability of a measuring instrument/measuring device.

The measuring equipment is assessed by repeatedly measuring the reference standard of the measuring system. The prerequisite here is that the "true" value of the reference standard used is documented and known via a calibration certificate. As a result, the measuring equipment potential Cgand the capability indexCgk (AIAG) orQMK for VDA Volume 5 are calculated.

We will be happy to advise you on an MSA according to procedure 2, procedure 3 or others.

Consulting Services